Rub Testing: Efficiently Testing Ink

Rub testing is key to the company’s being able to fulfill important orders for their customers. If a company utilizes less-than-excellent shipping materials, namely ink, the receiving end will be confused about what product they are receiving or even misuse the product. Rub testing is a method that utilizes a rub tester machine or a dual rub tester to see how well an ink can withstand jostling, friction, or even moisture exposure.

Why Is Rub Testing Important?

Ink is crucial to communicating a message effectively. Ink is used because of its permanent and durable traits; however, even ink can be worn away under tough conditions. Steris has a great example on their website: If a hospital equipment manufacturer ships a very specific machine to a hospital but the label has worn away during the shipping and handling process, the hospital may send the machine to the wrong part of the building or complex. This will cause problems and drastically affect customer satisfaction. The stakes only go up when considering even more sensitive materials like medicine or chemicals for a lab. Nobody wants to take the wrong medication–especially if there are negative side-effects. If a lab uses the wrongfully labeled materials, just because the ink was affected, a harmful reaction could take place and people could even get hurt.

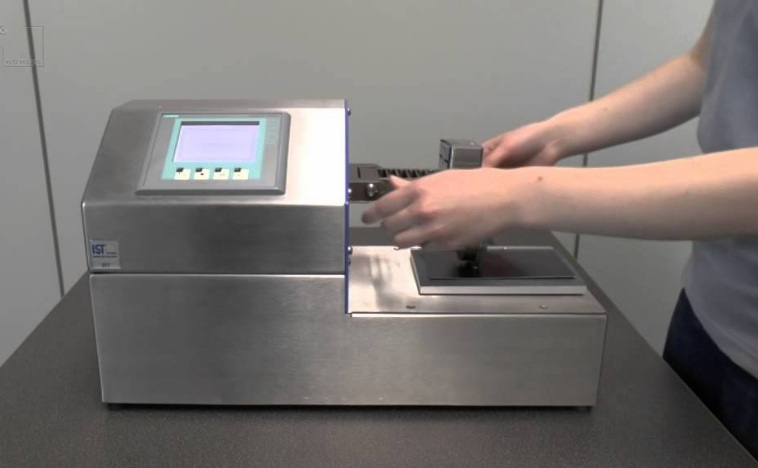

Dual Rub Tester

A dual rub tester is a unique piece of machinery that adds to the capabilities of a standard rub tester. Many of these machines are produced by Sutherland. A standard machine, according to the Thwing-Albert Instrument Company, is known for being able to expedite the testing process through varying speeds and enabling the ink to withstand both dry and wet conditions while being tested. Add a dual rub tester and a laboratory/company can test ink materials side by side–this, according to rubtester.com which is Sutherland’s website. Gone are the days where individuals testing the ink has to notate the exact time and conditions and then try to replicate the same conditions. Being able to use the same conditions at one time is the best way to maintain accuracy when testing one ink material against another. Gardo’s website emphasizes the machine’s ability to test the same material side by side but under different stresses.

A dual rub tester can move/ at varying speeds to show a substance’s strength and integrity under varying conditions and varying times. These speeds, according to rubtester.com are 21, 42, 85, or even 106 revolutions/cycles per minute. Additionally, Sutherland advertises flexibility in its dual rub tester in that there are customizable adapters to be added per customer request. While there are differing optional modifications that can be added to a rub tester to simulate the correct environment, a Sutherland machine (dual rub tester), according to Gardco’s website costs around $7,000 without the modifications that can be priced/purchased on the aforementioned website. Some of these optional equipment elements would be a heated pad to simulate a heated environment, weights, and rubber pads to be attached to the machine.