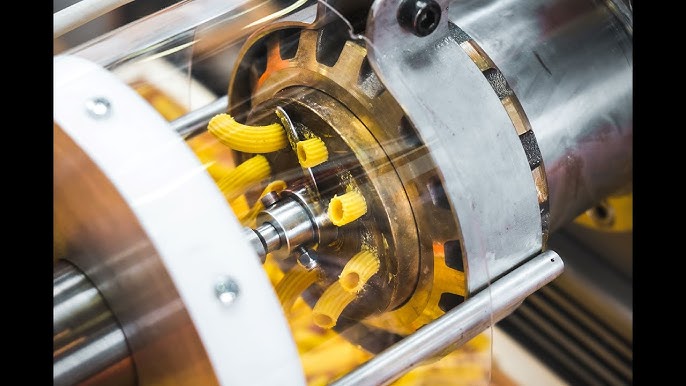

In food processing facilities, the operational demands placed on equipment rival those of heavy industrial applications, yet with an additional critical requirement: absolute food safety assurance. This unique challenge positions food grade lubricants at the intersection of engineering performance and consumer protection, requiring specialized formulations that perform under extreme conditions while meeting stringent regulatory standards.

The regulatory framework governing food grade lubricants spans multiple organizations including the FDA, USDA, and NSF International in the United States, and analogous bodies internationally. These authorities establish the certification processes, ingredient restrictions, and usage guidelines that define lubricant categories. H1 lubricants for incidental food contact receive particular scrutiny due to their potential to reach consumer products.

Modern food processing equipment presents significant lubrication challenges. Production lines often operate continuously with minimal downtime for maintenance. Processing areas may experience extreme temperature variations, frequent washdowns with caustic cleaning agents, and potential contamination from raw materials. Food grade lubricants must maintain performance characteristics under these demanding conditions.

The formulation science behind food grade lubricants represents a triumph of chemical engineering. Traditional performance additives common in industrial lubricants often cannot be used due to toxicity concerns. Formulators must instead develop alternative chemistry that delivers equivalent protection using only ingredients from approved lists. This constraint drives continuous innovation in the sector.

Risk management principles guide food manufacturers toward comprehensive lubricant programs that extend beyond product selection. Color-coded application tools, clear identification systems, segregated storage areas, and detailed documentation procedures all help prevent cross-contamination between food grade and non-food grade products. These systematic approaches support both operational efficiency and audit compliance.

The economic case for premium food grade lubricants becomes clear when considering the potential costs of contamination incidents. Product recalls, brand damage, regulatory penalties, and potential litigation expenses can reach millions of dollars even from minor incidents. Against these risks, the marginally higher cost of quality food grade lubricants represents sound business practice.

Changing consumer preferences have elevated the importance of additional certifications beyond basic food safety. Organic production, halal and kosher compliance, and allergen considerations may all influence lubricant selection in specialized applications. Leading suppliers provide transparency regarding these additional certifications to support diverse manufacturing requirements.

The future of food grade lubrication will likely feature increased integration with food safety management systems, enhanced traceability through digital documentation, and continued innovation in biodegradable formulations that maintain performance characteristics while improving environmental profiles.

For more information on food safety management, visit the Food Safety Preventive Controls Alliance or explore resources from the International Association for Food Protection.